In the world of heavy industry, construction, and engineering, few components are as fundamentally important yet frequently misunderstood as wire-rope. This complex and versatile machine component represents a marvel of mechanical engineering, far more sophisticated than a simple piece of metal. A wire-rope is a type of mechanical cable meticulously constructed from several strands of high-grade metal wire, each twisted into a precise helix. These individual strands are then themselves twisted together in a specific pattern around a central core to form the finished, high-strength product. Due to its exceptional strength-to-weight ratio and its unparalleled ability to handle immense static loads and dynamic forces, wire-rope has become an indispensable component in countless industries that form the backbone of the modern world, from massive construction projects and global transportation networks to demanding marine operations and deep mining activities.

While the precise technical term is wire-rope, this essential tool is frequently referred to by a number of other names in various professional contexts. The purpose of this comprehensive article is to clarify these common synonyms and related terminology, providing a clear and authoritative guide for engineers, project managers, and safety officers. Understanding what constitutes a wire-rope and its various designations, such as cable or steel cable, is absolutely essential for clear technical communication, proper application selection, and, most critically, for ensuring the highest standards of safety in any professional setting where it is used. This in-depth guide will help you navigate the precise language of wire-rope, explore its diverse constructions, and understand its critical role in a multitude of applications.

Decoding the Terminology: Common Names for Wire Rope

The widespread and critical use of wire-rope across a vast spectrum of industries has naturally led to the accumulation of a number of different names and terms. While these terms are often used interchangeably in casual conversation, they can sometimes refer to specific types, constructions, or dedicated applications. A clear understanding of this lexicon is the first step toward proper selection and safe usage.

Cable

The most universal and commonly used synonym for wire-rope is simply cable. This term is broadly and effectively used to describe any thick, strong rope or line designed for mechanical purposes. Its etymological roots trace back to the nautical term for a large rope used to secure a ship’s anchor, a testament to its long history of bearing heavy loads. In the modern context, cable is a general-purpose term that can refer to both electrical conductors and mechanical strength members. When a mechanical cable is specifically made of steel, it is often more precisely called a steel cable. A specific and important example is aircraft cable, which is a type of small-diameter, highly flexible and high-strength wire-rope, often constructed from stainless steel. It is frequently used for flight control systems, pulleys, and other mechanisms where precision and reliability are paramount, despite not being a part of the aircraft’s primary structural lift systems.

Steel Cable

The term steel cable explicitly emphasizes the material composition of the wire-rope. While the vast majority of wire ropes are indeed manufactured from various grades of steel, this specific term is often preferred in industries where the material specification is a critical design parameter. For example, in heavy construction, bridge building, or structural engineering, an engineer’s specification will likely call for a “high-tensile steel cable” to highlight its specific strength and material properties, ensuring the correct product is used. This term serves a vital function in differentiating these products from cables or ropes made of other materials like natural fiber, synthetic polymers such as nylon or polyester, or even other metals like aluminum.

Wire Rope Sling

A wire rope sling is not a raw product but a finished assembly specifically engineered and fabricated for the critical tasks of lifting, rigging, and hoisting. It is manufactured from a measured piece of wire-rope with a professional fitting or a spliced loop (an eye) at each end. These terminations allow the sling to be easily and securely attached to a load on one end and a lifting device, such as a crane hook or shackle, on the other. Slings come in a variety of standardized configurations, such as eye-and-eye slings, endless grommet slings, and braided slings, each uniquely suited for different lifting applications based on the weight, shape, and fragility of the load. The creation of a sling involves precise craftsmanship to ensure its safe working load limit is maintained.

Other Industry-Specific Terms

Different industries have developed their own specialized names for wire-rope based on its specific, and often highly demanding, use case.

Hoisting Cable: This term is predominantly used in the context of cranes, elevators, and hoists, where the primary function of the cable is the vertical lifting and lowering of heavy loads. These cables are engineered for high tensile strength and excellent fatigue resistance.

Winch Cable: This refers to a cable designed specifically for use with a winch, a device for pulling or towing loads horizontally. It is common in automotive recovery, logging, and marine applications, where its construction may be optimized for abrasion resistance as it spools on and off a drum.

Guy Wire: This is a stationary cable used to provide lateral stability and support to a tall, free-standing structure like a radio transmission tower, electricity pylon, or large antenna. It is typically under high static tension.

Mooring Line: In marine applications, this is a heavy-duty, often massive wire-rope used to secure a ship, oil rig, or other floating vessel to a dock, pier, or buoy. These lines must withstand immense forces from currents, winds, and tides and are almost always heavily galvanized for corrosion protection.

Table 1: Common Wire Rope Terminology and Their Primary Applications

| Term | Definition | Primary Industry/Use |

|---|---|---|

| Cable / Steel Cable | General term for a mechanical wire rope | Universal across all industries |

| Wire Rope Sling | An assembly with end fittings for lifting | Lifting, rigging, and hoisting |

| Hoisting Cable | Cable designed for vertical lifting | Cranes, elevators, mining hoists |

| Winch Cable | Cable designed for horizontal pulling | Automotive, logging, marine winches |

| Guy Wire | A stationary cable providing stability | Construction, telecommunications, utilities |

| Mooring Line | Heavy-duty cable for securing vessels | Marine and offshore industries |

A Deep Dive into the Types and Constructions of Wire Rope

Wire-rope is not a single, monolithic product but rather a extensive category of engineered components with a vast array of types, each meticulously designed for specific performance requirements and operational environments. These types are primarily distinguished by their internal construction—the architecture of how the wires and strands are arranged—and the materials from which they are made.

Classification Based on Construction

The construction of a wire-rope is its blueprint, referring to how the individual wires are laid to form a strand and, crucially, how these strands are then laid around the core to form the final rope. This geometry dictates its fundamental behavior.

Lay Direction: The lay refers to the direction of twist imparted during the stranding and closing processes. There are two primary types. Regular Lay is the most common and versatile construction. Here, the wires in the strands are twisted in one direction, while the strands themselves are twisted in the opposite direction around the core. This counter-twisting results in a rope that is naturally torque-balanced, stable, and far less prone to kinking or unraveling during handling. Lang Lay is a more specialized construction where both the wires within the strands and the strands around the core are twisted in the same direction. This alignment creates a rope with a longer exposed wire length on the surface, granting it superior flexibility and greater resistance to abrasive wear. However, this same characteristic makes it more prone to kinking and rotation under load, so it is typically only used in applications where both ends of the rope are securely fixed to prevent rotation, such in some crane hoist lines or dredge lines.

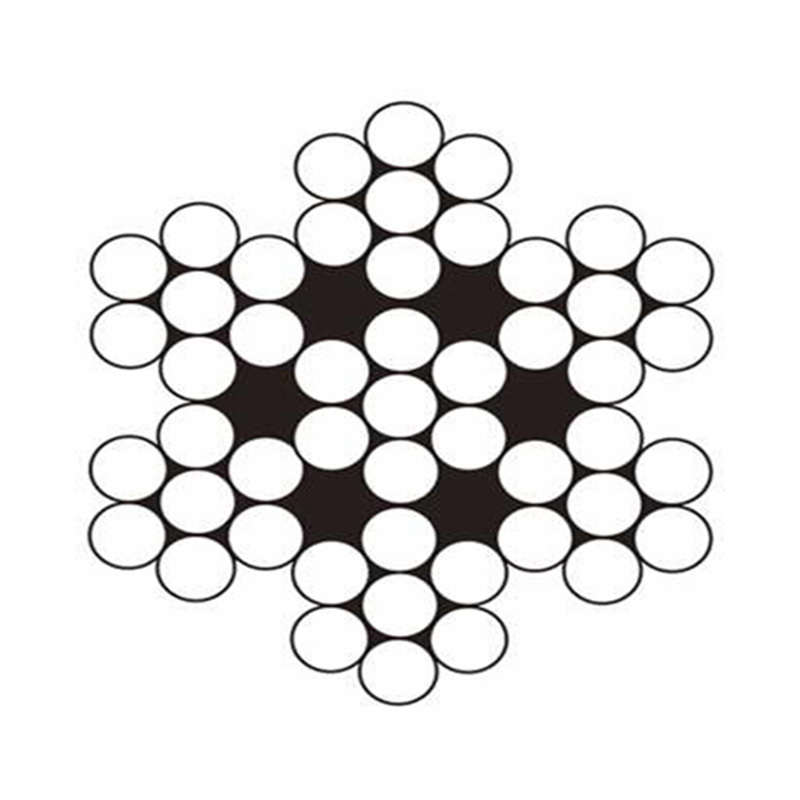

Strand Count and Configuration: Wire ropes are systematically classified by the number of strands and the number of wires per strand. This is denoted in a format like “6x19” where ‘6’ is the number of strands and ‘19’ is the number of wires in each strand (though ‘19’ often represents a class or range, e.g., 16 to 26 wires). This configuration directly and profoundly impacts the rope’s flexibility and fatigue resistance. A rope with more, finer wires per strand (e.g., an 8x19 or 6x36 construction) will be significantly more flexible and resistant to bending fatigue, making it ideal for applications with frequent movement over sheaves. Conversely, a rope with fewer, larger wires (e.g., a 6x7 or 7x7 construction) will be more rigid and offer superior resistance to abrasion and crushing, suited for more static applications like guy wires.

Core Type: The central core of the wire-rope is a critical component that provides essential internal support for the outer strands, maintaining their positional integrity under load. There are two main categories. A Fiber Core (FC), typically made of natural materials like sisal or synthetic polymers like polypropylene, provides excellent flexibility, elasticity, and shock absorption. It also acts as a reservoir to help retain lubricant within the core of the rope. However, it is susceptible to damage from excessive heat and moisture and offers lower strength compared to a steel core. A Steel Core provides superior mechanical properties. It can be either an Independent Wire Rope Core (IWRC), which is a separate smaller wire rope itself, or a Wire Strand Core (WSC). A steel core offers significantly higher tensile strength, enhanced resistance to crushing forces, and much greater tolerance to heat. It is, however, less flexible and is typically used in the most demanding applications like mining hoist lines, high-temperature environments, or where crushing loads are a concern.

Classification Based on Material and Coating

The base material and any protective coatings applied to the wire-rope are carefully chosen based on the intended application and the environmental conditions it will be subjected to throughout its service life.

Different Grades of Steel: The overwhelming majority of wire ropes are manufactured from high-carbon steel, which is cold-drawn to achieve its maximum tensile strength. However, for applications that demand exceptional corrosion resistance, stainless steel wire rope is the material of choice. Grades like 304 and, more commonly for harsh environments, 316 stainless steel are used in marine environments, chemical processing plants, food and beverage production, and anywhere else exposed to moisture and corrosive agents. It is important to note that stainless steel offers lower breaking strength than a similarly sized carbon steel rope but provides far greater durability and service life in corrosive conditions.

Protective Coatings: To enhance the lifespan of carbon steel ropes, various coatings are applied. Galvanized Wire Rope is a very common and effective type where the individual wires are coated with a layer of zinc through a hot-dip or electroplating process. This zinc coating provides a durable, sacrificial barrier against rust and corrosion, making it the standard choice for outdoor construction, marine applications, and any environment with exposure to moisture. Bright (Uncoated) Wire Rope has no protective metallic coating. It is typically used in dry, indoor, non-corrosive environments or in situations where the rope will be regularly maintained with external lubrication and is subject to frequent inspection. PVC/Plastic Coated Wire Rope involves extruding a layer of plastic or vinyl over the finished wire rope. This coating provides maximum protection against corrosion and chemicals. It also adds a layer of safety by containing broken wires and preventing splinters, making it suitable for applications like handrails, animal fencing, or in environments with high chemical exposure.

The Critical Applications of Wire Rope Across Global Industries

Wire-rope is a fundamental and often irreplaceable component in a vast number of industries, performing critical functions where immense strength, reliability, and long-term durability are non-negotiable requirements. Its versatility allows it to be engineered and specified for a breathtakingly wide range of specific applications, each with its own unique set of demands.

Construction and Infrastructure

In the construction industry, wire-rope is utterly indispensable for lifting, hoisting, and providing vital structural support. Tower cranes and mobile cranes rely on large-diameter hoisting cables to lift and move phenomenally heavy loads, from structural steel beams to pre-fabricated concrete slabs, hundreds of feet into the air. Passenger and freight elevators use specialized, high-cycle wire-rope hoisting ropes engineered for both immense strength and a exceptionally high degree of fatigue resistance to ensure absolute safety over millions of lifting cycles. Furthermore, lighter-duty cables are integral to systems like suspended scaffolding, providing secure temporary access for workers on skyscrapers and bridges.

Marine and Offshore

The marine environment is one of the most demanding applications for wire-rope, requiring products with exceptional corrosion resistance and tremendous strength to withstand the relentless forces of the ocean. Heavy-duty mooring lines, constructed from heavily galvanized or stainless steel ropes, are used to secure massive container ships, tankers, and offshore oil rigs to anchors or docks, resisting the power of currents, winds, and tides. Large towing vessels use immense steel cables to pull barges, disabled ships, or other non-motorized vessels across oceans. On a smaller scale, stainless steel cables are used for the standing and running rigging on sailboats, controlling sails and supporting masts.

Mining and Resource Extraction

In mining operations, which represent some of the most severe duty cycles for any equipment, wire-rope is used for the critical tasks of lifting, hauling, and excavating in both open-pit and deep underground settings. In deep shaft mines, massive multi-strand wire-ropes are used in hoisting systems to raise and lower cages carrying personnel, ore, and heavy equipment thousands of feet to the surface. Above ground, enormous excavators and draglines use robust wire-ropes to control the massive buckets and booms that move millions of tons of rock and soil.

Other Essential Industries

The applications of wire-rope extend seamlessly into many other sectors. In the automotive industry, it is used in vehicle control systems, such as brake and clutch cables, and in mechanisms like garage door openers. The aerospace sector relies on high-strength, lightweight aircraft cables for flight control surfaces and other critical systems where reliability is paramount. Transportation infrastructure utilizes wire-rope in the cables for ski lifts, gondolas, and cable cars, safely moving passengers over challenging terrain. Even the entertainment industry depends on it; in theaters and on movie sets, wire-rope is silently at work suspending heavy props, lighting rigs, and even performers for aerial sequences.

Key Engineering Considerations When Selecting Wire Rope

Selecting the correct wire-rope for a specific application is a complex engineering decision that is critical for achieving both optimal performance and absolute safety. The wrong choice can lead to premature failure, costly operational downtime, equipment damage, and even catastrophic accidents. Here are the most important factors that must be meticulously considered during the selection process.

Strength and Load Capacity Analysis

The most fundamental and non-negotiable consideration is whether the wire-rope is strong enough to safely handle the intended loads it will encounter throughout its service life.

Working Load Limit (WLL): The WLL, sometimes called the Safe Working Load (SWL), is the maximum load that should ever be applied to a wire-rope in a given application under normal service conditions. It is not a property measured by testing but is instead assigned by the manufacturer based on the rope’s known breaking strength and a predetermined safety factor. It is the paramount value that must never be exceeded in practice.

Breaking Strength and Safety Factor: The Minimum Breaking Strength (MBS) or Minimum Breaking Load (MBL) is the minimum force required to cause a new, unused wire-rope to fail in a tensile test. The relationship between the WLL and the MBS is defined by the Design Factor or Safety Factor. For example, a safety factor of 5:1 means the breaking strength is five times greater than the working load limit. This factor is not arbitrary; it is carefully chosen based on the application’s risk profile. Lifting personnel, for instance, requires a much higher safety factor (often 10:1 or more) than lifting inanimate objects in a controlled environment (which may be 5:1). Understanding and applying the correct safety factor is the cornerstone of safe rigging and lifting operations.

Environmental and Operational Factors

The environment in which the wire-rope will operate has a profound impact on its performance, degradation rate, and ultimate service life.

Corrosion Resistance: This is perhaps the most critical environmental factor. In marine, chemical, or consistently high-moisture environments, the risk of rust and corrosive attack is extreme. For these conditions, stainless steel wire rope (especially Grade 316) is the ideal choice due to its superior inherent resistance. For general outdoor use where moisture is present but chemicals are not, a galvanized wire rope, with its protective zinc coating, offers an excellent balance of performance and cost-effectiveness. Using an uncoated rope in a corrosive environment will lead to rapid failure.

Temperature Ranges: Extreme temperatures can severely affect the metallurgical properties and lubricants within a wire-rope. High temperatures can anneal the steel (reducing its strength), degrade a fiber core, and break down lubricants. Conversely, very low temperatures can make the steel more brittle and reduce its impact resistance. Always ensure the selected wire-rope is rated and lubricated for the specific temperature range of the application, especially in settings like steel mills or cryogenic facilities.

Flexibility and Fatigue Resistance

The mechanical duty cycle of the application dictates the required flexibility and fatigue performance of the wire-rope.

Flexibility Requirement: A more flexible rope is mandatory for applications where it must bend frequently and tightly, such as when running over sheaves or wrapping around a drum. Flexibility is primarily a function of construction. As a rule, a rope with a higher number of smaller wires (e.g., a 6x36 or 8x19) will be much more flexible than a rope of the same diameter with fewer, larger wires (e.g., a 6x7).

Fatigue Resistance: Metal fatigue is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading. For a wire-rope, this is the weakening caused by repeated bending under tension. Fatigue failure is a primary cause of wire rope breakdown in dynamic applications like cranes. Ropes with more, finer wires are generally more resistant to bending fatigue. Furthermore, using a sheave or drum with a diameter that is too small for the wire-rope will dramatically increase bending stress and exponentially accelerate fatigue, making proper sheave-to-rope diameter ratios a critical design consideration.

Table 2: Wire Rope Selection Guide Based on Key Application Factors

| Primary Application Factor | Recommended Wire Rope Feature | Reasoning |

|---|---|---|

| High Corrosion Environment (e.g., marine) | Stainless Steel (Grade 316) or Heavily Galvanized | Superior resistance to rust and pitting from saltwater and moisture. |

| High Abrasion Environment (e.g., mining) | Lang Lay, 6x19 or 6x21 Class | Longer wire exposure on surface provides better wear resistance. |

| High Flexibility Needed (e.g., over sheaves) | 8x19, 6x36, or 6x41 Class Constructions | More, finer wires allow for tighter bending without failure. |

| High Strength & Crush Resistance (e.g., hoisting) | IWRC (Independent Wire Rope Core) | Steel core provides highest strength and resists crushing on the drum. |

| Static Application (e.g., guy wires) | 6x7 or 7x7 Class, Galvanized | Fewer, larger wires provide high strength and abrasion resistance for fixed lines. |

Ensuring Safety and Longevity: Wire Rope Maintenance and Inspection Protocols

The safe and effective use of wire-rope is entirely dependent on the implementation of rigorous maintenance, handling, and inspection procedures. Neglecting these protocols is the leading cause of preventable failure. Adhering to a strict safety standard is therefore non-negotiable for any organization that relies on this equipment.

Systematic Inspection Procedures

Regular and meticulous inspections are the most effective way to monitor the condition of a wire-rope and proactively identify issues before they lead to failure. Inspections should be performed at multiple levels: a daily visual check by the equipment operator and a thorough periodic inspection by a qualified and competent person.

Regular Visual Inspections: The operator should check the entire length of the rope for any obvious signs of wear or damage before each use. This includes looking for broken wires, which can protrude and form a “bird cage,” evidence of severe corrosion that has pitted the wires, kinks that have permanently deformed the rope, or any sections that have been flattened or crushed. Particular attention must be paid to critical zones: the sections that pass over sheaves, contact the drum, or are exposed to frequent friction points.

Discard Criteria: A wire-rope must be immediately removed from service if it meets any of the discard criteria established by stringent industry standards. These standards provide clear, quantitative guidelines for condemnation. Common criteria include the presence of a specified number of broken wires in one rope lay (e.g., six broken wires in one lay length for a 6x19 rope), three or more broken wires in one single strand within one lay length, evidence of severe corrosion that has caused measurable reduction in rope diameter, any visible kinks, crushing, or heat damage (which can change the steel’s color), and significant loss of rope diameter due to wear or core failure.

The Critical Role of Lubrication

Lubrication is not an optional maintenance task; it is a critical life-saving function for a wire-rope. It serves two primary purposes: reducing internal friction and providing corrosion protection.

Importance of Lubrication: During operation, the individual wires and strands within a wire-rope constantly move against each other as the rope bends and adjusts under load. This movement generates internal friction, which leads to wear and metal fatigue. A proper lubricant minimizes this friction, significantly extending the rope’s service life by reducing internal wear. Secondly, the lubricant acts as a barrier, protecting the steel surfaces from moisture and oxygen, thereby preventing corrosion that starts from within the core.

Types and Application of Lubricants: Lubricants designed for wire-rope are specially formulated to be both penetrating and adhesive. They are thin enough to wick into the core of the rope but sticky enough to remain in place and not be flung off during operation. Never use general-purpose grease or motor oil, as they often lack the necessary properties and can even attract dirt that accelerates abrasion. Lubrication should be applied regularly as part of a scheduled maintenance program, with frequency determined by the severity of service.

Proper Handling and Storage Protocols

How a wire-rope is handled and stored before it is even put into service can have a major impact on its performance and lifespan.

Avoiding Mechanical Damage: A wire-rope should never be dragged over abrasive surfaces like concrete or sharp edges, as this can instantly damage or break the outer wires. It should never be forced into a loop with a radius smaller than its minimum bend radius, as this can cause a permanent and dangerous kink. When cutting a wire-rope, proper techniques and tools (like seizing and a shear or abrasive cut-off wheel) must be used to prevent the rope from unlaying.

Correct Storage Methods: New or unused wire-rope should always be stored on a reel or coiled neatly on a clean, dry surface. It must be kept off the ground in a well-ventilated area to prevent moisture accumulation and chemical contamination. Exposure to acids, solvents, or other corrosive agents in storage can initiate damage that compromises the rope’s integrity once placed into service.

Conclusion: The Engineered Backbone of Modern Industry

Wire-rope, in all its forms and under all its names, is a deceptively simple yet incredibly highly engineered tool that forms the literal and metaphorical backbone of countless industries that power modern civilization. Its effectiveness, reliability, and, most importantly, its safety are a direct result of its carefully designed construction, precise material composition, and, ultimately, the knowledge and diligence of those who specify, use, and maintain it.

Understanding the various terminologies for wire-rope, from the general steel cable to the specific hoisting cable or guy wire, is essential for clear technical communication and for selecting the absolutely correct type for a specific, often safety-critical, application. Engineering factors like the working load limit, required corrosion resistance, and necessary flexibility must be analyzed carefully and systematically to ensure both operational efficiency and unwavering safety. Above all, an organizational commitment to regular inspection, proper lubrication, and conscientious handling is the single most important factor in maximizing the performance, ensuring the reliability, and extending the service life of your wire-rope assets. By rigorously following these engineering principles and maintenance guidelines, you ensure not only the productivity of your operations but, most critically, the safety and well-being of the personnel who depend on this equipment every day.

English

English Español

Español Deutsch

Deutsch 日本語

日本語