How to Select the Right Korean Standard Link Chain for Heavy-Duty Operations

Selecting the correct Korean Standard Link Chain is essential for safety, durability, and operational efficiency in lifting, rigging, and cargo control. The guidance below outlines practical criteria and checkpoints to help you make a reliable, audit-ready choice.

Core Selection Principles

1) Define the Working Load Limit (WLL) and Safety Factor

Start by calculating the maximum expected load and the dynamic effects of the operation (shock, angle factors, start/stop cycles). Choose a chain whose Working Load Limit exceeds this value with an appropriate safety factor based on your use case and regulations.

- Account for sling angles in multi-leg lifts.

- Consider duty cycles and frequency of use to avoid fatigue failure.

- Never exceed the WLL stamped or certified for the chain size and grade.

2) Verify Compliance with Korean Standards and Relevant International Norms

Confirm that the chain is manufactured to recognized Korean standards and, where applicable, harmonized requirements used in your destination market. Compliance ensures consistent metallurgy, heat treatment, dimensions, and mechanical properties.

- Request mill certificates and mechanical test reports.

- Ensure dimensional tolerances match your hooks, shackles, and hoists.

3) Select the Appropriate Chain Grade and Size

Higher grades provide higher strength for the same diameter, which can reduce weight while maintaining capacity. Match the grade and nominal diameter to the required WLL and the hardware you will connect.

- Confirm pitch, inside length, and inside width to ensure hardware fit.

- Use only grade-compatible components across the lifting system.

4) Choose Material and Surface Protection for the Environment

Operating conditions drive material and finish decisions. Corrosive, marine, or abrasive environments require enhanced protection.

- Alloy steel with controlled heat treatment for high-strength lifting.

- Galvanized or specialty-coated finishes for outdoor or marine exposure.

- Consider additional wear protection if running over sheaves or sharp edges.

5) Assess Compatibility with System Components

The chain must work seamlessly with hooks, master links, connectors, binders, and hoists.

- Check latch and throat opening sizes of hooks against chain dimensions.

- Confirm connector designs (e.g., clevis, omega links) are approved for the chain grade.

- Ensure hoists and lever tools are rated for the selected grade and diameter.

6) Plan for Inspection, Traceability, and Maintenance

Heavy-duty operations demand predictable lifecycle management.

- Specify batch traceability (heat numbers, lot IDs) and clear product markings.

- Adopt routine visual and dimensional inspections (elongation, wear, corrosion, cracks).

- Establish retirement criteria for wear, deformation, and corrosion depth.

7) Confirm Certifications, Testing, and Documentation

Robust documentation reduces risk and simplifies audits.

- Request proof load and break load test data for representative batches.

- Keep certificates of conformity and user instructions accessible on site.

Application-Focused Guidance

Lifting and Rigging

- Prioritize higher strength grades with tight dimensional tolerances.

- Use marked components with matching grade and WLL; avoid mixing grades.

- Include angle reductions in sling WLL calculations.

Cargo Control and Transport

- Balance strength with flexibility and ease of handling.

- Choose finishes suitable for weather exposure; inspect after impact events.

- Verify binder and ratchet compatibility to prevent point loading.

Construction, Mining, and Marine

- Favor coatings or galvanization for corrosion resistance.

- Increase inspection frequency under abrasive or chemical exposure.

- Use protective sleeves or edge guards where contact with sharp edges is unavoidable.

Why Shanghai TCH Metals & Machinery Co., Ltd.

Shanghai TCH Metals & Machinery Co., Ltd. is a leading company specializing in the manufacturing and distribution of metals and machinery in the Shanghai region. With a strong focus on quality, innovation, and customer satisfaction, the company has established itself as a trusted partner for businesses in various industries.

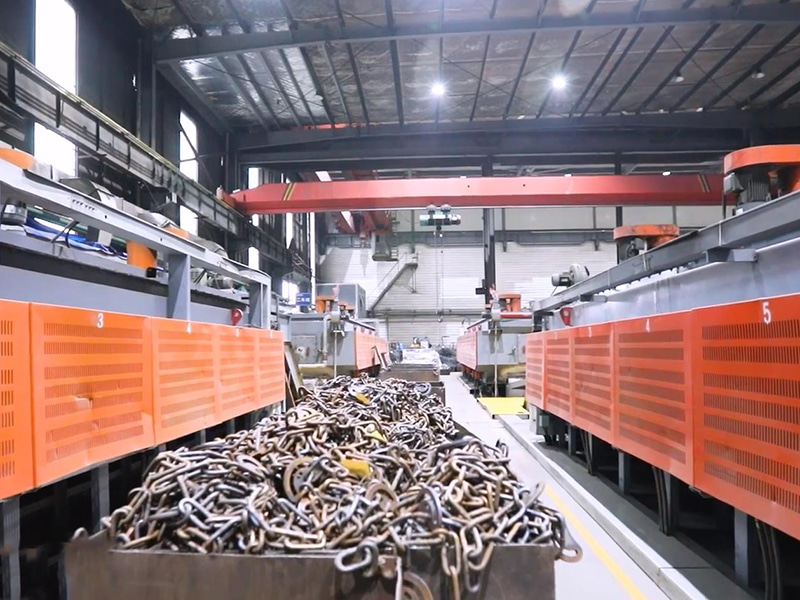

Backed by a state-of-the-art manufacturing facility equipped with the latest technology and machinery, Shanghai TCH Metals & Machinery Co., Ltd. delivers consistent quality and efficiency. The product portfolio covers chains, tire chains, slings, wire ropes, cargo controls, rigging hardware, metal sheets, pipes, fittings, and machinery parts—supporting diverse operational needs from lifting to logistics.

Established in 2001 and serving clients across North America, Europe, and Japan, Shanghai TCH Metals & Machinery Co., Ltd. combines proven expertise with responsive after-sales service. The company's team of skilled professionals provides application-driven recommendations, documentation support (testing, certificates), and tailored solutions that align with demanding heavy-duty requirements.

For Korean Standard Link Chain selection, the company helps specify the correct grade, diameter, finish, and compatible hardware, while setting up inspection and maintenance plans that extend service life and reduce downtime.

Practical Buying Checklist

- Defined WLL (including angle and shock factors) and chosen safety factor.

- Confirmed compliance with Korean standards and relevant market norms.

- Selected grade and diameter matching capacity and hardware interfaces.

- Specified finish for the environment (galvanized or specialty coatings as needed).

- Verified component compatibility across the entire system.

- Arranged for certificates, batch traceability, and proof/break test data.

- Established inspection intervals and retirement criteria before deployment.

Conclusion

The right Korean Standard Link Chain balances capacity, compliance, durability, and system compatibility. By applying the selection principles above and partnering with Shanghai TCH Metals & Machinery Co., Ltd., heavy-duty operators gain reliable product performance, end-to-end documentation, and responsive technical support for safe, efficient operations.

How Korean Standard Link Chain Ensures Safety and Efficiency in Cargo Control

Korean Standard Link Chain plays a critical role in securing loads across trucking, marine, warehousing, and industrial logistics. Its standardized geometry, material quality, and predictable mechanical performance help prevent load shifts, protect personnel and assets, and streamline day-to-day operations.

Core Safety Principles

Uniform Strength and Dimensional Consistency

Standardized link dimensions and controlled heat treatment deliver consistent strength from link to link, reducing weak points and minimizing failure risks during dynamic transport conditions such as braking, cornering, and impact.

Working Load Limit and Safety Factors

Clear markings and documentation support correct Working Load Limit application. Applying appropriate safety factors for shock loads and angle effects ensures the system remains within safe operating limits.

System-Level Compatibility

Consistent link geometry enables reliable interface with binders, hooks, ratchets, and anchors, reducing misfits and unsafe point loading that can compromise the entire cargo restraint system.

Operational Efficiency Gains

Faster Securement and Release

Smooth, repeatable fit with hardware speeds up lashing, tensioning, and inspection, cutting loading bay dwell time and improving fleet utilization.

Lower Lifecycle Cost

High wear resistance and robust coatings reduce replacements and unplanned downtime. Predictable service life simplifies maintenance planning and inventory control.

Traceability and Audit Readiness

Batch traceability and certificates streamline compliance checks and incident investigations, keeping operations audit-ready without excessive administrative overhead.

Selection Guidance for Cargo Control

Choose the Right Grade and Diameter

Match chain grade and size to the required Working Load Limit, accounting for shock loads, multi-point tie-downs, and the weakest component in the system.

Confirm Environmental Protection

For coastal or winter road service, specify galvanized or specialty-coated chains to resist corrosion and abrasion. In abrasive yards, consider enhanced wear properties.

Verify Hardware Compatibility

Ensure hooks, binders, and anchor points are rated for the same or higher grade and that throat openings, latch designs, and radii align with the chain's link dimensions.

Documentation and Markings

Require clear markings, batch IDs, and access to proof and break load data. Keep certificates with fleet records for quick reference and training.

Best Practices in Daily Use

Pre-Use Checks

Inspect for elongation, bent links, corrosion pitting, and cracked welds. Replace chains showing wear beyond your retirement criteria or any deformation.

Correct Tensioning

Apply even tension across all tie-down points. Avoid sharp edges by using corner protectors or sleeves to minimize localized wear and potential cutting.

Storage and Handling

Store clean and dry, off the ground, away from chemicals. Lubricate as recommended to reduce fretting corrosion and to ease handling in cold conditions.

Common Mistakes to Avoid

Mixing Grades or Underrated Hardware

The system is only as strong as its weakest link. Do not mix grades or use accessories with lower WLL than the chain.

Ignoring Angle and Shock Factors

Recalculate effective WLL when chains are used at angles or in applications with dynamic loading, such as heavy equipment transport.

Running Past Retirement Criteria

Set clear limits for wear, corrosion depth, and permanent elongation. Replace chains promptly to avoid progressive damage and unexpected failures.

Application Scenarios

Long-Haul Trucking

Use grade-appropriate chains with compatible binders for machinery and steel loads. Re-check tension during the first kilometers and at routine stops.

Port and Marine Operations

Favor corrosion-resistant finishes and increase inspection frequency due to salt exposure and impact loading during vessel movements.

Construction and Heavy Equipment

Account for frequent shock loads and abrasive environments. Use edge protection on bucket lips, blade edges, and frames.

Why Partner with Shanghai TCH Metals & Machinery Co., Ltd.

Proven Manufacturing Capability

Shanghai TCH Metals & Machinery Co., Ltd. operates a state-of-the-art facility in Shanghai, leveraging advanced machinery and quality controls to deliver consistent, high-performance chains and related cargo control products.

Broad Product Ecosystem

The company provides chains, tire chains, slings, wire ropes, cargo controls, rigging hardware, as well as metal sheets, pipes, fittings, and machinery parts—covering end-to-end needs from securement to structural components.

Global Reach and Service

Since 2001, Shanghai TCH Metals & Machinery Co., Ltd. has built a strong presence across North America, Europe, and Japan. A focus on innovation, documentation support, and responsive after-sales service has earned long-term client trust, particularly in demanding markets.

Application-Driven Engineering Support

Skilled professionals help specify grade, diameter, finish, and compatible hardware for your cargo types and routes. The team also assists with inspection protocols, retirement criteria, and training materials to elevate safety and efficiency.

Implementation Checklist

Pre-Purchase

Define WLL and safety factors, confirm environmental needs, ensure documentation requirements, and verify hardware compatibility across the system.

Deployment

Label and record batch IDs, train crews on tensioning and inspection, and establish interval checks aligned with route risk and usage frequency.

Lifecycle

Track service hours, record defects, and retire chains per criteria. Schedule periodic audits to validate compliance and update procedures.

FAQs

How do I choose between finishes?

For coastal, winter, or chemical exposure, select galvanized or specialty coatings. For dry indoor use, standard finishes may suffice with routine care.

Can I mix different chain sizes?

Avoid mixing sizes or grades within a single restraint system. Keep components matched to the highest required WLL and the same geometry class.

What documentation should I keep?

Maintain certificates of conformity, batch IDs, proof and break load data, inspection logs, and crew training records for audits and incident reviews.

Conclusion

Korean Standard Link Chain enhances cargo control by pairing standardized safety with operational efficiency. When specified, applied, and maintained correctly, it reduces risk, speeds workflows, and lowers lifecycle cost. Partnering with Shanghai TCH Metals & Machinery Co., Ltd. provides access to high-quality products, end-to-end documentation, and expert support—ensuring your loads arrive safely, efficiently, and compliantly.

English

English Español

Español Deutsch

Deutsch 日本語

日本語