Norwegian Standard Link Chain: The Key to Long-Term Reliable Operation Through Safety and Maintenance

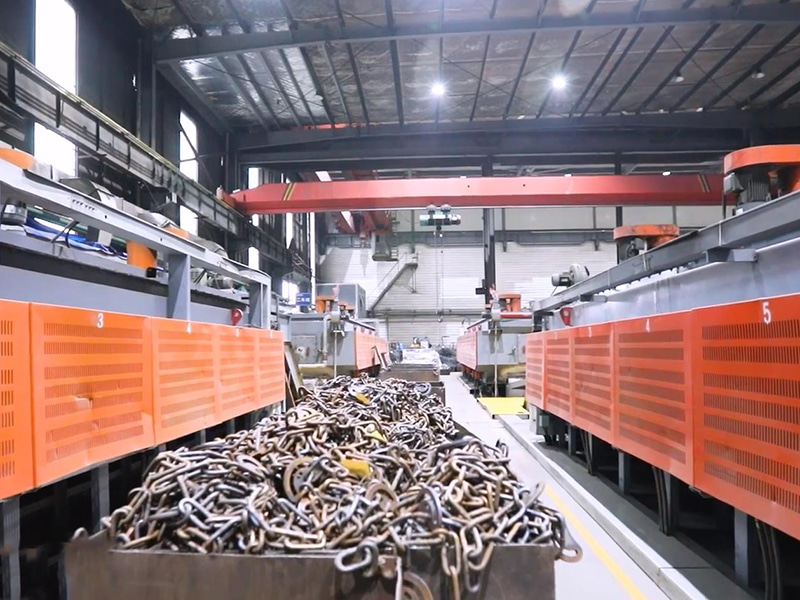

A Commitment to Quality from Shanghai TCH Metals & Machinery Co., Ltd.

For any high-strength, heavy-duty mechanical component, safety inspection and daily maintenance are the lifelines that ensure long-term reliable operation. This is especially critical for Norwegian Standard Link Chains, which are widely used in demanding environments like marine, fishing, and oil drilling operations. As a professional China Norwegian Standard Link Chain Manufacturer and Custom Norwegian Standard Link Chain Factory, Shanghai TCH Metals & Machinery Co., Ltd. understands this importance and adheres strictly to the highest quality standards in every stage of product design, production, and delivery. We also provide comprehensive maintenance guidance to our customers.

Safety Inspection: A Non-Negotiable Guarantee for Life

Over long periods of use, chains can develop potential risks from wear, corrosion, or accidental impact. To ensure safety, regular professional inspections are a must. Shanghai TCH Metals & Machinery Co., Ltd. utilizes advanced non-destructive testing technologies, such as:

- Magnetic Particle Testing: By applying a magnetic field to the chain's surface and sprinkling magnetic powder, this method can clearly reveal tiny surface cracks and defects that are invisible to the naked eye.

- Ultrasonic Testing: This technique uses high-frequency sound waves to penetrate the interior of the chain, detecting any internal pores, inclusions, or un-welded areas, thereby ensuring the material's integrity.

We firmly believe that only through strict quality control and comprehensive pre-delivery inspections can we ensure that every single chain meets its design strength and safe working load capacity.

Daily Maintenance: The Key to Extending Chain Lifespan

Even the most robust chains require careful maintenance to prevent performance degradation. Proper upkeep can significantly extend a chain's service life and reduce the risk of accidents. We advise our customers to follow these key maintenance points:

| Regular Inspections | Before each use, visually inspect the chain for any signs of deformation, twisting, cracks, or severe rust. Pay close attention to the connections between links, as these areas are most prone to wear. |

| Cleaning and Lubrication | Promptly clean any dirt, sand, or salt from the chain's surface. In dry and corrosive environments, regularly apply a specialized lubricant or rust inhibitor to form a protective film that reduces wear and corrosion. |

| Proper Storage | When not in use, store the chain in a dry, well-ventilated area away from direct sunlight and moisture. If it will be stored for an extended period, it's best to hang it or lay it flat to prevent stacking or tangling. |

As a leading company in the Shanghai region known for quality and innovation, Shanghai TCH Metals & Machinery Co., Ltd. not only provides Norwegian Standard Link Chain products that meet strict industry standards, but we are also dedicated to offering comprehensive technical support and maintenance advice to our customers. We believe that a combination of superior product quality and scientific maintenance practices is what truly guarantees the long-term reliable operation of chains under all demanding conditions, thereby safeguarding our customers' business operations.

English

English Español

Español Deutsch

Deutsch 日本語

日本語