The Complete Guide to Producing Ordinary Mild Steel Link Chains

As a leading China Ordinary Mild Steel Link Chain Manufacturer and Custom Ordinary Mild Steel Link Chain Factory, Shanghai TCH Metals & Machinery Co., Ltd. leverages its expertise in the metals and machinery sector to provide customers with high-quality chain products. Our production process is meticulous and efficient, ensuring every chain meets the highest quality standards. Here are the key steps in producing ordinary mild steel link chains:

1. Raw Material Preparation and Selection

The first step in production is selecting high-quality raw materials. We use low-carbon steel wire rod that complies with international standards. This material is ideal for chain manufacturing due to its excellent ductility and weldability. At Shanghai TCH Metals & Machinery Co., Ltd., we conduct stringent quality checks on all raw materials to ensure their chemical composition and physical properties meet production requirements.

2. Forming (Straightening and Cutting)

The prepared steel wire rod is first fed through a straightening machine to make it straight. Then, a precise cutting machine cuts the rod into specific lengths, which determine the size of the final chain link. Our advanced equipment ensures cutting accuracy, which is a solid foundation for subsequent processes.

3. Bending and Shaping

The cut steel segments are then sent to an automatic bending machine. This machine bends the segments into the shape of a chain link, bringing the two ends close to each other but not yet closing them. This process requires high-precision equipment to ensure the geometric shape of the links is consistent.

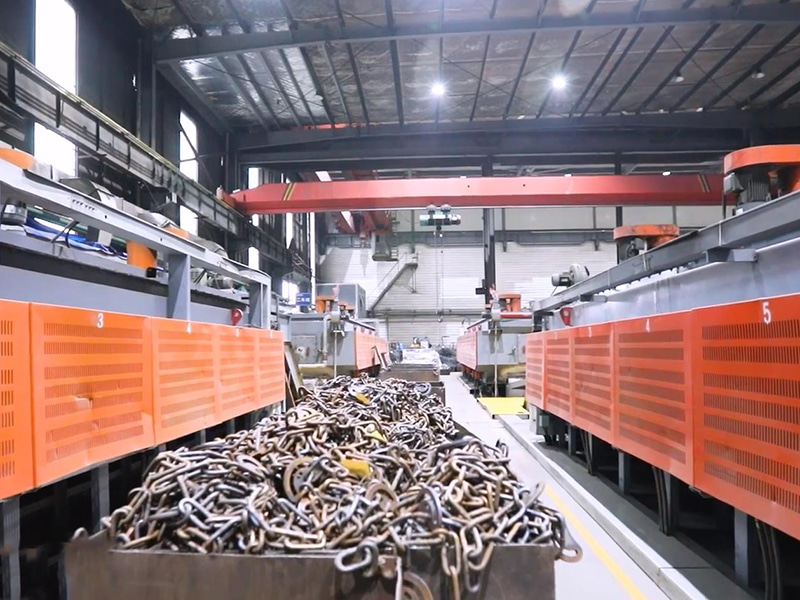

4. Welding (Butt Welding)

This is a critical step in the chain manufacturing process. In the butt welding process, the two ends of the chain link are joined tightly. A powerful electric current generates instantaneous high heat, melting the connection point, which is then fused together under mechanical pressure to form a complete ring. Shanghai TCH Metals & Machinery Co., Ltd. uses cutting-edge welding technology to ensure every weld is strong and reliable, without any defects, guaranteeing the chain's safety and strength.

5. Calibration and Gauging

After welding, the chain links may be slightly deformed due to the high temperature. Therefore, each link needs to be precisely calibrated using a calibrating machine to ensure its size and shape conform to standards. At the same time, the gauging process ensures that the internal length of each link remains consistent, which is crucial for the smooth operation of the chain.

6. Surface Treatment and Anti-Corrosion

To enhance the chain's corrosion resistance and aesthetics, a surface treatment is necessary. Common treatment methods include galvanizing, nickel plating, or painting. Galvanizing is the most common surface treatment for chains, as it effectively prevents rust. As a custom chain factory, we can provide different surface treatment options based on the client's specific needs.

7. Quality Inspection and Packaging

After all processes are complete, every batch of chains must undergo rigorous quality inspection. This includes tensile strength testing, fatigue testing, and visual inspection. Our quality control team ensures that every link of the chain meets industry standards and customer requirements. The compliant chains are then carefully packaged and prepared for shipping.

With our professional manufacturing processes, state-of-the-art equipment, and commitment to quality, Shanghai TCH Metals & Machinery Co., Ltd. ensures that every chain we produce can meet the demanding requirements of customers in various industries, solidifying our leading position in the metals and machinery sector.

English

English Español

Español Deutsch

Deutsch 日本語

日本語