I. Introduction: What is a Webbing Sling and Why is it So Important?

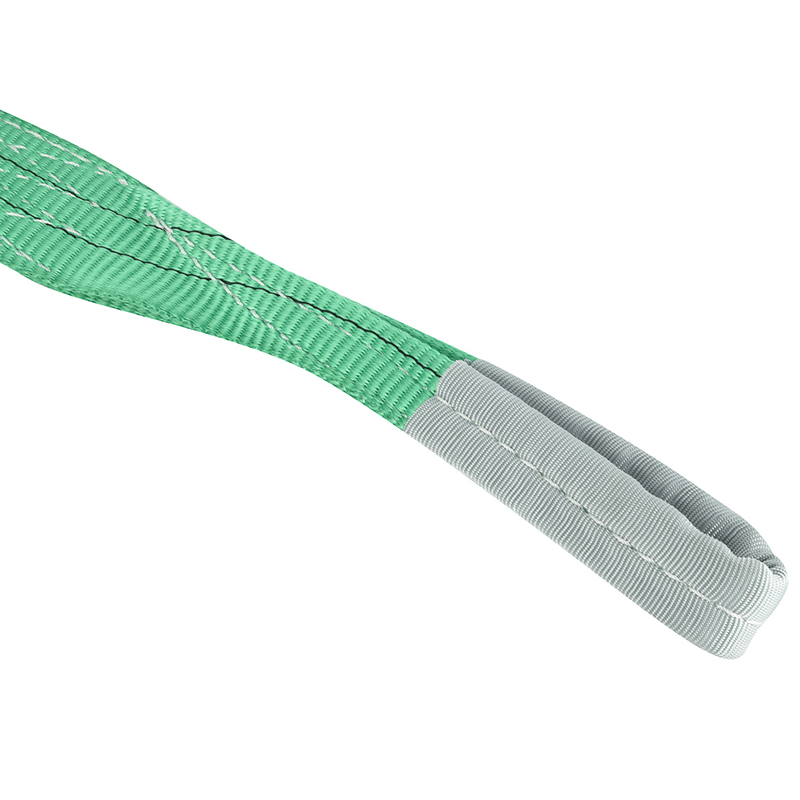

A webbing sling, at its core, is a length of high-tensile synthetic fibre woven into a strong, flat, and flexible belt. It is a fundamental piece of equipment designed for lifting, securing, and moving heavy loads across various industries.

You might wonder, how can a simple-looking strap safely support weights of several tons? The answer lies in its engineered strength and design. Unlike rigid chains or metal ropes, webbing slings are lightweight and non-marring, meaning they protect the surface finish of the loads they carry. Their flexibility allows them to conform securely to awkward shapes, providing a stable and balanced lift.

The true importance of the webbing sling, however, goes beyond its physical capabilities. It is a critical component for workplace safety. Proper use prevents costly damage to goods and, more importantly, protects personnel from the severe dangers of load failure. To harness these benefits and ensure safety, it is essential to understand a few key aspects: its types, color codes, capacity, material, and rigging methods.

II. Understanding the Different Types of Webbing Sling

Choosing the right type of webbing sling is the first step in ensuring a safe and efficient lift. The most common classifications are based on their configuration and end fittings, each designed for specific applications.

The two primary types you will encounter are:

- Flat Eye Sling: This is the most recognizable and widely used type. It features a flat, reinforced loop (or "eye") at each end. These eyes are used to connect the sling to the lifting hooks of a crane or hoist. Flat eye slings are versatile and ideal for straightforward, direct lifting tasks.

- Endless Sling (or Grommet Sling): This type is constructed as one continuous loop of webbing, with no separate end fittings. Its seamless design makes it particularly strong and allows it to be used in a "basket" configuration with ease. Endless slings are excellent for handling delicate or finished surfaces, as the webbing distributes pressure over a larger area, and for lifting large, cylindrical objects like pipes or drums.

Understanding these fundamental types allows you to select the right tool for the job, whether you need to "lift" from two points with an eye sling or "cradle" a load with an endless sling.

III. Decoding the Color Code: Quickly Identifying Webbing Sling Capacity

A webbing sling's capacity, or its Safe Working Load (SWL), is its most critical characteristic. Exceeding this limit can lead to catastrophic failure. To enable immediate and easy identification of a sling's strength, a universal color-coding system is employed. This system serves as the first and most visual line of defense against dangerous overload situations.

The color is typically woven into the edge of the sling or appears as a strand within the webbing itself, creating a quick-reference guide for operators on the job site. It is crucial to remember that this color corresponds to the sling's SWL when used in a straight, vertical lift (a configuration known as a vertical hitch).

The following table outlines the standard color code and its associated capacities for the most common types of webbing slings. It is important to note that while this is a widely adopted standard, you should always consult the permanent, sewn-on tag on the sling for the definitive and legally recognized SWL, as specifications can vary by manufacturer and region.

Webbing Sling Color Code & Capacity Reference

| Sling Color | Safe Working Load (SWL) - Vertical Hitch | Common Width & Thickness Range | Typical Application / Context |

|---|---|---|---|

| Purple | 1 Ton (1,000 kg / 2,200 lbs) | Narrower widths (e.g., 1" - 2") | Lighter machinery components, palletized goods, and general warehouse lifting tasks. |

| Green | 2 Tons (2,000 kg / 4,400 lbs) | Medium widths | A versatile capacity for construction materials, industrial equipment, and standard rigging setups. |

| Yellow | 3 Tons (3,000 kg / 6,600 lbs) | Medium to wider widths | Common for heavier machinery, steel beams, and prefabricated structures. |

| Grey | 4 Tons (4,000 kg / 8,800 lbs) | Wider, heavier webbing | Used in heavier industrial applications, such as in fabrication shops and for large concrete elements. |

| Red | 5 Tons (5,000 kg / 11,000 lbs) | Substantial width and thickness | Reserved for the heaviest-duty lifts, often in steel mills, shipbuilding, and major construction projects. |

| Brown | 6 Tons (6,000 kg / 13,200 lbs) | Very wide and thick webbing | Specialized applications requiring extreme strength for massive, concentrated loads. |

| Blue | 8 Tons (8,000 kg / 17,600 lbs) | Extra-wide and heavy-duty webbing | Used in the most demanding industrial environments for lifting immense weights. |

| Orange | 10 Tons (10,000 kg / 22,000 lbs) | Maximum width and thickness | For the most extreme and engineered heavy-lift operations. |

However, relying on color alone is not sufficient. The color code is an excellent tool for quick checks and inventory management, but it is not a substitute for a thorough inspection of the sling's official data tag. This permanently affixed tag provides the most accurate and legally binding information, including the precise SWL, the manufacturer's name, the material type (e.g., polyester), and the sling's unique identification number. The tag's information takes precedence over the general color code.

Furthermore, it is vital to understand that this color-coded capacity is only valid for a vertical lift. As soon as the sling is used in a different rigging configuration—such as a basket hitch or a choke hitch—the sling's effective, usable capacity changes, often significantly. Therefore, while the color code tells you the sling's intrinsic strength, the actual safe load it can bear in a real-world lift depends on how it is rigged. This crucial relationship between color, capacity, and configuration forms the foundation of safe webbing sling operation.

IV. Beyond Color: An In-Depth Understanding of Webbing Sling Capacity

While the color code provides an immediate visual cue, a truly comprehensive understanding of a webbing sling's capacity requires looking deeper. The Safe Working Load (SWL) is not an arbitrary number; it is a carefully calculated value derived from a complex interplay of factors, all designed to build in a critical margin of safety. Understanding these factors is what separates basic recognition from professional, safe rigging practices.

The most fundamental concept to grasp is the Safety Factor (also known as the Design Factor). This is the ratio between the sling's minimum breaking strength (the point at which it will actually fail) and its stated Safe Working Load. For webbing slings, this factor is typically very high, often 5:1 or even higher. This means a sling rated for a 2-ton SWL has been designed and tested to not break until at least 10 tons of force is applied. This substantial buffer accounts for unseen wear and tear, dynamic forces (shock loading), and other unpredictable stresses encountered in real-world lifting scenarios.

Beyond the safety factor, several physical and environmental characteristics directly influence a sling's rated capacity and its performance in the field. The following table outlines these key factors beyond the basic color code.

| Factor | Description & Impact on Capacity | Practical Implication |

|---|---|---|

| Material & Construction | The inherent strength of the synthetic fiber (e.g., polyester, nylon) and the weave density (e.g., number of picks per inch) determine the baseline strength. A heavier, tighter weave generally yields a higher capacity. | Always check the tag for the material type, as different materials have different strength and elongation properties, which can affect the SWL. |

| Width & Thickness | Capacity is directly proportional to the cross-sectional area of the webbing that bears the load. A wider and thicker sling will have a higher SWL than a narrower, thinner one of the same material. | A 4-inch wide polyester sling will have a significantly higher SWL than a 2-inch wide sling made from the same material. |

| Sling Length | While the length of a sling does not change its fundamental SWL in a vertical hitch, it can influence capacity in choker hitches due to the increased friction and sharper bend radius around the load. | Longer slings may have derated capacities for choker hitches compared to shorter slings of the same width and material. |

| Rigging Configuration | This is arguably the most critical variable after the sling's intrinsic SWL. As introduced earlier, the way a sling is used alters its effective capacity. | A sling must be derated based on the hitch type (e.g., Choker hitch can reduce capacity to 75-80% of vertical SWL). The angle between multiple legs also drastically increases the tension on each leg. |

| Environmental Conditions | Exposure to chemicals, UV radiation (prolonged sunlight), extreme temperatures, and abrasion can degrade the synthetic fibers over time, effectively reducing the sling's strength and thus its safe working capacity. | A sling used in a chemical plant may have a different service life and capacity retention than one used indoors. Regular inspection is vital to account for this degradation. |

The Critical Role of the Data Tag:

The sewn-in, permanent data tag is the ultimate source of truth for a webbing sling's capacity. It is a legal document that certifies the sling's specifications. The information on this tag incorporates all the factors listed above—material, construction, width, length, and the specific SWL for different hitch configurations (Vertical, Basket, Choker). The color code is a useful quick-check tool, but the data tag provides the precise, non-negotiable limits for safe operation. If the tag is missing, illegible, or damaged, the sling must be immediately removed from service.

The Angle Effect: A Hidden Force Multiplier

A discussion of capacity is incomplete without emphasizing the dramatic impact of lift angles. When a sling is used in a two-leg basket hitch or with two separate slings, the angle formed between the legs (known as the included angle) creates forces that can far exceed the actual weight of the load. As this angle widens, the tension on each leg increases exponentially. For example, a 1,000 kg load lifted with a 120-degree angle between the legs places over 1,000 kg of tension on each leg—effectively doubling the force. This is why understanding the actual tension on the sling, not just the load's weight, is a fundamental part of deeply understanding webbing sling capacity.

V. Why Choose Polyester? The Critical Role of Material

The material from which a webbing sling is constructed is not merely a detail; it is a fundamental determinant of its performance, safety, and suitability for specific tasks. Among the various synthetic fibers available, polyester has emerged as the predominant and most versatile choice for a wide range of general industrial lifting applications. Understanding its properties allows you to appreciate why it is so widely specified.

Polyester webbing slings offer a superior balance of strength, safety, and environmental resistance. The key advantages that make polyester a top choice include:

- High Strength with Low Elongation: Polyester possesses a very high tensile strength, allowing it to handle heavy loads. Crucially, it has a relatively low elongation at break compared to materials like nylon. This means it stretches less under load, providing greater control and stability during the lift and preventing the load from shifting excessively.

- Excellent Load Protection: The combination of strength, flexibility, and a smooth, flat surface makes polyester slings exceptionally good at protecting delicate loads. They will not mar, scratch, or damage polished surfaces, painted finishes, or fragile materials, eliminating the need for additional protective padding in most cases.

- Superior Chemical Resistance (Especially to Acids): This is one of polyester's most significant advantages. It exhibits excellent resistance to most weak acids and a wide range of other chemicals that are commonly found in industrial settings, such as those in chemical processing, plating, and battery manufacturing. This resistance prevents the rapid degradation of the fibers that can occur with other materials.

- Good Abrasion Resistance: The tough nature of polyester fibers grants it good durability against wear and tear from rough surfaces, contributing to a longer service life when used and inspected properly.

To fully contextualize the benefits of polyester, it is helpful to compare it with other common webbing sling materials. The following table outlines the key characteristics, providing a clear rationale for why polyester is often the default selection.

Comparison of Common Webbing Sling Materials

| Material | Key Advantages | Key Limitations & Considerations | Ideal Application Context |

|---|---|---|---|

| Polyester | Excellent balance of strength and low stretch. Superior resistance to weak acids and many chemicals. Excellent load protection. Good abrasion resistance. | Susceptible to degradation from strong alkalis and hot steam. Resistance to solvents is variable. | The go-to choice for general industrial lifting, especially in environments with chemical exposure (acids), and for lifting delicate or finished surfaces. |

| Nylon | Very high strength and exceptional elasticity (high elongation). Excellent resistance to alkalis and hydrocarbons. Superior energy absorption, making it good for absorbing shock loads. | Significantly reduced strength when wet (loses 10-15%). Poor resistance to strong acids. Its high stretch can lead to less load control. | Ideal for lifting in environments with alkaline chemicals or for applications where some shock absorption is beneficial, such as lifting from water or in damp conditions where its buoyancy is an advantage. |

| Polypropylene | Lightweight and it floats on water. Highly resistant to moisture and most acids, alkalis, and solvents. It is also an electrical insulator. | Lowest melting point and poor resistance to UV radiation. Lower overall strength and abrasion resistance compared to polyester and nylon. | Best suited for lightweight, occasional lifts, aquatic environments, and applications involving highly corrosive chemicals where its specific resistance is required. Often used for one-time use or "disposable" slings. |

Making the Informed Choice

The decision ultimately hinges on the specific operational environment and the nature of the load. Polyester's standout performance in acid resistance and its optimal balance of strength with minimal stretch make it the most reliable and widely applicable material for the majority of lifting scenarios. It effectively mitigates the key weaknesses of nylon (water absorption, acid sensitivity) and polypropylene (low strength, UV and heat sensitivity), while offering its own unique set of protective benefits. Therefore, when the application does not specifically call for the shock-absorbing quality of nylon or the unique chemical buoyancy of polypropylene, polyester consistently proves to be the most prudent and high-performing choice for a webbing sling.

VI. Proper Rigging: How to Maximize the Efficiency of Your Webbing Sling

Selecting the correct webbing sling—considering its type, capacity, and material—is only half the battle. The final and most critical step that determines both safety and efficiency is its rigging configuration. How a sling is arranged around the load and connected to the lifting hook directly dictates its effective Safe Working Load (SWL). Using a sling correctly can maximize its potential, while incorrect rigging can dangerously overload it even when lifting a load well below its rated capacity. Understanding the three fundamental hitch types and the critical impact of the angle between legs is non-negotiable for safe operation.

The three basic rigging configurations each have distinct mechanical behaviors and corresponding effects on the sling's usable capacity.

- Vertical Hitch (Single Leg): This is the simplest configuration, where the sling is used in a straight, vertical line from the lifting hook to the load. In this setup, the entire load is supported by a single leg. The effective SWL is simply the rated capacity of the sling as listed on its data tag for a vertical hitch.

- Basket Hitch: In this configuration, the sling is passed under the load, and both ends are connected to the lifting hook, forming a "basket" that cradles the load. When rigged with the legs vertical, a true basket hitch can double the sling's effective SWL because the load is distributed equally between the two legs of the same sling. However, it is crucial to ensure the sling is not pinched or crushed at the bottom of the basket, and the stability of the load must be carefully considered.

- Choker Hitch: This method involves passing one end of the sling through the other eye to form a loop that tightens around the load. While excellent for securing loose or smooth items, the sharp bend and friction significantly reduce the sling's capacity. A standard choker hitch typically reduces the effective SWL to approximately 75-80% of the vertical hitch rating due to the stress concentration at the choke point.

The following table provides a clear comparison of these hitches and their direct impact on lifting capacity.

Comparison of Fundamental Webbing Sling Hitch Configurations

| Hitch Type | Description & Illustration | Effective Safe Working Load (SWL) | Key Considerations & Best Practices |

|---|---|---|---|

| Vertical Hitch | A single, straight leg between the hook and the load. | 100% of the sling's rated vertical SWL. | Simplest to use. Provides full lifting height. The load must have a reliable lifting point. |

| Basket Hitch | The sling cradles the load, with both eyes connected to the hook. | Up to 200% of the sling's rated vertical SWL (i.e., double). | Critical: The capacity is halved if the legs are not vertical. Provides excellent stability and protects the load. Avoid sharp edges under the load. |

| Choker Hitch | A loop is formed that tightens around the load when lifted. | Typically 75-80% of the sling's rated vertical SWL. | Excellent for securing loose materials (pipes, logs). The choke point must be on the sling body, not the tag. Never knot the sling. |

The Critical Impact of the Sling Angle

When using a basket hitch with two slings or a two-leg arrangement, a new and powerful variable is introduced: the sling angle or included angle. This is the angle formed between the two legs of the sling(s). This angle is not a minor detail; it is a force multiplier that dramatically increases the tension experienced by each leg.

As the sling angle widens, the tension in each leg increases exponentially. This is because the horizontal forces generated by the angled legs must be balanced, and these forces add to the vertical load. For example, to lift a 1,000 kg load:

- With a 60° included angle, the tension on each leg is about 580 kg.

- With a 90° included angle, the tension on each leg jumps to about 700 kg.

- With a 120° included angle, the tension on each leg soars to 1,000 kg—effectively equaling the entire weight of the load on each leg.

This is why a wide sling angle is one of the most common and dangerous rigging mistakes. It can easily overload slings even when the total load seems well within their combined capacity. Always aim to keep the included angle below 90 degrees, and use an angle factor calculation to determine the actual tension on each leg before lifting. By mastering these configurations and respecting the critical role of angles, you can ensure your webbing sling is not only safe but is also working at its maximum designed efficiency.

VII. Conclusion and Safety Checklist

Throughout this guide, we have deconstructed the webbing sling into its core components: Type, Color Code, Capacity, Material, and Rigging. It is crucial to understand that safe and efficient lifting is not about focusing on just one of these elements, but about seeing them as an interconnected system. The correct sling type ensures a proper fit for the load, the color code and data tag provide the foundational strength parameters, the material choice guarantees environmental suitability, and the rigging configuration ultimately determines the real-world, effective capacity. Mastering the relationship between these factors—especially the dramatic impact of sling angles and hitch types—is the essence of professional rigging practice.

Theoretical knowledge, however, must be cemented with disciplined practice. To ensure that every lift is conducted with the highest regard for safety, the following actionable checklist should be used as a pre-operational routine. This list integrates all the concepts discussed previously into a step-by-step verification process.

Webbing Sling Pre-Use Safety Checklist

| Checkpoint Category | Specific Action Items & Verification Criteria |

|---|---|

| 1. Pre-Use Inspection |

|

| 2. Capacity & Identification |

|

| 3. Configuration & Setup |

|

| 4. Load Security & Stability |

|

| 5. Final Operational Check |

|

A Culture of Safety

Adhering to this checklist is more than a procedure; it is the foundation of a safety-first culture. Remember, a webbing sling is a robust but passive tool. Its safety is entirely dependent on the knowledge, vigilance, and disciplined practices of the user. If a sling fails an inspection point—if in doubt, take it out. Removing a damaged sling from service is not a loss; it is an investment in preventing a potentially catastrophic incident. By consistently applying the principles outlined in this guide and rigorously following this safety checklist, you empower yourself to harness the full potential of webbing slings while ensuring the well-being of all personnel and the security of every load.

Frequently Asked Questions (FAQ)

1. Q: Can I use a webbing sling if its color code is visible but the data tag is missing or unreadable?

A: No, you must not use it. The permanent, sewn-in data tag is the legal and definitive record of the sling's specifications, including its exact Safe Working Load (SWL) for different hitch types. The color code is only a quick-reference guide. A missing or illegible tag means the sling's capacity cannot be verified with certainty, and it must be immediately removed from service to prevent the risk of an overload failure.

2. Q: I need to lift a load in an environment with both acids and alkalis present. Is a polyester webbing sling still the best choice?

A: This is a high-risk scenario that requires careful assessment. While polyester offers excellent resistance to weak acids, it is susceptible to degradation from strong alkalis. In such a mixed chemical environment, the specific concentration and temperature of the chemicals are critical. A generic polyester sling may not be adequate. For these complex situations, a professional risk assessment is essential, and you should consult with a specialist lifting equipment provider who can advise on a sling material with the correct chemical resistance for your specific operational hazards.

3. Q: When using a two-legged basket hitch, the load is within the sling's capacity, but the angle between the legs is very wide (over 120 degrees). Is this safe?

A: This is potentially very dangerous. A wide angle dramatically increases the tension force on each leg of the sling. At a 120-degree included angle, the tension on each leg is equal to the entire weight of the load. This means your slings could be experiencing twice the force you might intuitively expect, putting them at a high risk of overload. You should always aim to keep the included angle below 90 degrees. To achieve this, use a longer sling or a different lifting point to create a narrower, safer angle before proceeding with the lift.

English

English Español

Español Deutsch

Deutsch 日本語

日本語