How to Choose the Right Australian Standard Chain? Key Factors and Application Scenarios

Choosing the right Australian Standard Chain requires a comprehensive consideration of several key factors, combined with specific application scenarios. As a professional Australian Standard Chain Manufacturer and custom factory, Shanghai TCH Metals & Machinery Co., Ltd. can help you make an informed choice.

Key Factors

The following points are crucial when selecting a chain:

Material

The material of the chain directly determines its strength, wear resistance, and corrosion resistance. Common materials include carbon steel, alloy steel, and stainless steel. For example, in a humid or corrosive environment, a stainless steel chain is a better choice, while alloy steel is more suitable for applications requiring high-strength load-bearing.

Size and Specification

Ensure that the chain's dimensions (such as pitch, roller diameter, and inner width) meet your equipment requirements. Australian Standard Chains typically comply with the AS 2321 standard, which has strict regulations for dimensions and performance parameters. Correctly matching the size is fundamental to ensuring the safe and efficient operation of your equipment.

Working Load Limit (WLL)

When selecting a chain, you must consider its maximum working load, ensuring that the chain's rated load is much greater than the anticipated load in the actual application. This usually requires considering a safety factor to handle sudden overloads.

Operating Environment

The operating environment of the chain, such as temperature, humidity, and whether it is exposed to chemicals or dust, will affect its performance and lifespan. For example, in high-temperature environments, a specially heat-treated chain should be selected; in dusty environments, more attention should be paid to the chain's sealing and lubrication.

Application Scenarios

Different industries have different requirements for chains:

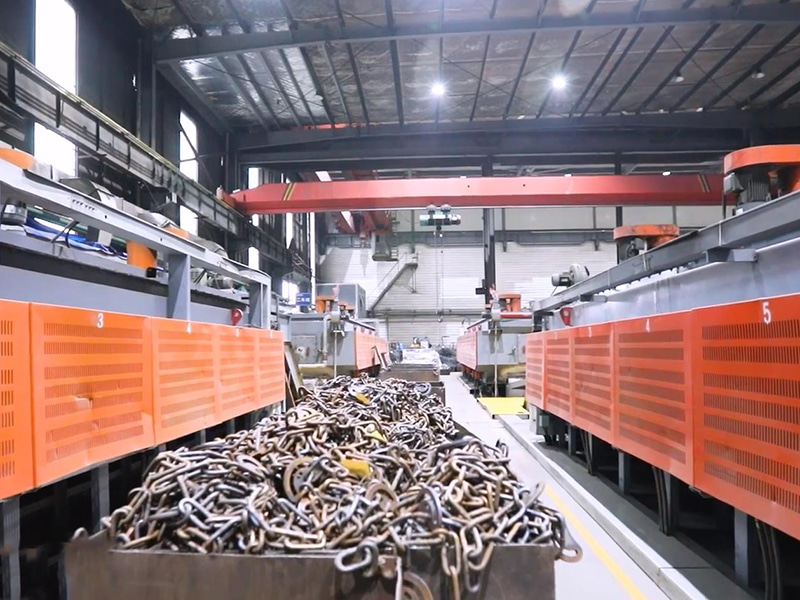

Mining and Construction

These two industries typically require high-strength, wear-resistant chains to withstand heavy loads, impacts, and harsh environments. The chains produced by Shanghai TCH Metals & Machinery Co., Ltd. can meet these demanding conditions, ensuring the reliable operation of equipment such as excavators, conveyors, and cranes.

Agriculture

In agricultural machinery, chains are often used for transmission and conveying. These applications usually require chains with good corrosion resistance to withstand the erosion from pesticides and fertilizers.

Industrial Manufacturing

In automated production lines, conveying systems, and material handling equipment, high-precision, low-noise chains are required. Choosing a precision chain that complies with the AS 2321 standard can ensure the smooth and efficient flow of production.

Shanghai TCH Metals & Machinery Co., Ltd., as a professional Custom Australian Standard Chain Factory, not only provides standard products but can also customize chains according to your specific needs, perfectly matching your application scenarios. By comprehensively considering the key factors above and our professional advice, you can choose the most suitable chain to ensure your equipment operates safely, efficiently, and durably.

English

English Español

Español Deutsch

Deutsch 日本語

日本語