When it comes to heavy lifting in industries like construction, shipping, and manufacturing, using the correct rigging hardware is crucial for safety and efficiency. Rigging hardware refers to a variety of components that help lift, move, or secure heavy loads.

What Is Rigging Hardware?

Rigging hardware encompasses a wide range of tools and components used for lifting, pulling, or securing heavy objects. These components are essential in many industries, particularly those where heavy machinery or cargo needs to be safely moved. Rigging hardware can include slings, hooks, shackles, pulleys, and more. Each of these components has a unique purpose and must be selected based on the load’s weight, shape, and type of lift required.

Essential Types of Rigging Hardware for Heavy Lifting

-

Shackles

Shackles are critical components in rigging hardware. They are used to connect two pieces of rigging hardware, such as hooks or slings, to the load. Shackles come in several types, including bow shackles, D-shackles, and galvanized chain shackles. The latter, in particular, is favored for its corrosion-resistant properties, making it suitable for marine and outdoor environments.- Bow Shackles: These are typically used for general lifting purposes. They have a rounded design that allows for better load distribution.

- D-Shackles: These are used for more heavy-duty lifting, offering a higher load capacity and greater strength.

- Galvanized Chain Shackles: These are designed to resist rust and corrosion, making them ideal for use in harsh conditions such as offshore lifting or industrial settings where exposure to moisture is frequent.

-

Hooks

Rigging hooks are essential in heavy lifting, providing a reliable means to connect the load to lifting equipment. There are various types of hooks, each suited for specific tasks:- Lifting Hooks: These are designed to attach to slings, chains, or cables. They are commonly used in lifting operations where the load needs to be easily attached and detached.

- Grab Hooks: These are used to securely latch onto a chain and are particularly helpful in applications where the load may shift or move.

- Eye Hooks: These are equipped with an eye at the top, allowing them to be connected to ropes or cables. Eye hooks are commonly used for hoisting operations.

-

Slings

Slings are used to secure a load during lifting. They come in several materials, including synthetic, wire rope, and chain. The type of sling chosen will depend on the weight of the load and the lifting conditions.- Wire Rope Slings: Known for their durability and high strength, wire rope slings are commonly used in heavy-duty lifting.

- Chain Slings: Chain slings are often used for lifting hot or sharp-edged loads due to their toughness and resistance to damage.

- Synthetic Slings: These are lightweight, flexible, and gentle on delicate loads, making them ideal for lifting fragile items.

-

Pulleys and Blocks

Pulleys and blocks play a vital role in changing the direction of force during lifting. They help reduce the force required to lift heavy loads by providing mechanical advantage.- Single Sheave Pulleys: These are used in applications where the lifting direction needs to be altered.

- Double and Triple Sheave Blocks: These are used to increase the lifting capacity and provide more mechanical advantage, especially in heavy lifting scenarios.

-

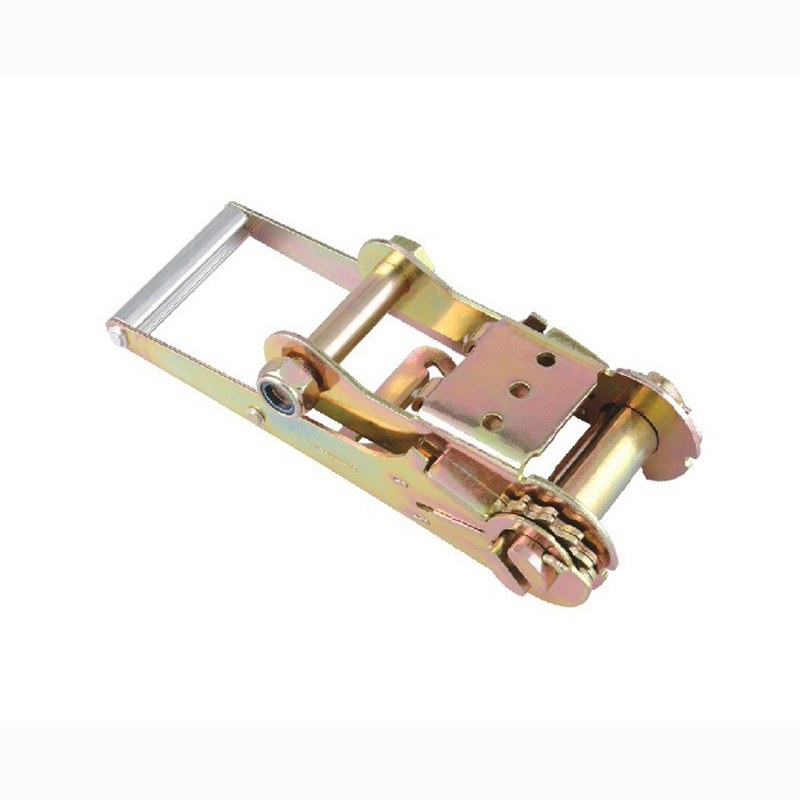

Turnbuckles

Turnbuckles are used to adjust the tension of a rope, chain, or cable. They are commonly used in rigging systems that require precise control of the load. Turnbuckles can be adjusted by rotating them to either tighten or loosen the connection. -

Ropes and Cables

Ropes and cables are often used in lifting operations where flexibility and ease of movement are essential. While rope is suitable for lighter loads, cables made of steel or other high-strength materials are used for heavier, more critical lifts.- Steel Wire Rope: Strong and durable, steel wire ropes are commonly used in cranes and winches.

- Synthetic Ropes: Lighter and more flexible, synthetic ropes are used in applications that do not involve extremely heavy loads.

-

Eyebolts

Eyebolts are used for securing lifting equipment to a load. They have a loop at the top that allows them to be attached to rigging hardware like slings or chains. Eyebolts are often used in lifting operations where precision and secure attachment are required. -

Snatch Blocks

Snatch blocks are used for lifting heavy loads by providing a way to change the direction of the pulling force. They allow for better control of the load and reduce the need for additional lifting equipment.

How to Choose the Right Rigging Hardware

Selecting the appropriate rigging hardware is crucial for ensuring safety during lifting operations. Here are some factors to consider:

- Weight of the Load: The hardware chosen should have a load capacity greater than the weight of the item being lifted.

- Environmental Conditions: For outdoor or marine environments, corrosion-resistant materials such as galvanized components should be used.

- Type of Lift: Depending on whether the lift requires a vertical or horizontal direction, different rigging hardware components may be needed.

- Frequency of Use: For heavy-duty, repetitive lifting tasks, durable and high-capacity rigging hardware should be chosen.

Table of Rigging Hardware Types and Their Applications

| Rigging Hardware Type | Material | Common Applications | Load Capacity |

|---|---|---|---|

| Shackles | Steel, Galvanized | Connecting slings, hooks, and other components | Varies (up to several tons) |

| Hooks | Steel, Alloy | Attaching slings and chains to loads | Varies by type |

| Slings | Wire rope, Synthetic, Chain | Securing loads for lifting operations | Varies (up to several tons) |

| Pulleys | Steel, Aluminum | Changing lifting direction | Varies by design |

| Turnbuckles | Steel, Galvanized | Adjusting tension in ropes and cables | Varies by size |

| Ropes and Cables | Steel, Synthetic | Lifting and pulling tasks | Varies by material |

| Eyebolts | Steel, Galvanized | Securing lifting equipment to the load | Varies by size |

| Snatch Blocks | Steel, Alloy | Reducing lifting force by changing direction | Varies by size |

FAQ

1. What is the difference between a galvanized chain shackle and a regular shackle?

Galvanized chain shackles are coated with a layer of zinc, which makes them resistant to rust and corrosion, making them ideal for use in harsh or outdoor environments.

2. How do I choose the right size of rigging hardware for my load?

The size of the rigging hardware should always exceed the weight of the load being lifted. Always check the manufacturer’s load rating to ensure the hardware can safely handle the weight.

3. What are the most common materials used in rigging hardware?

Rigging hardware is typically made from steel, stainless steel, and galvanized steel, with some components made from synthetic materials for specific applications.

4. Are synthetic slings as strong as steel slings?

While steel slings are generally stronger and more durable, synthetic slings offer benefits such as lighter weight and flexibility. The choice depends on the application and the load being lifted.

5. Can I reuse rigging hardware after a lifting operation?

Yes, but it is crucial to inspect the rigging hardware for any signs of wear, corrosion, or damage before reuse. Components that show signs of degradation should be replaced.

Conclusion

Rigging hardware is essential in heavy lifting, and the choice of components must be carefully considered for each specific task. From shackles to pulleys and turnbuckles, each piece of rigging hardware plays a vital role in ensuring the safety and efficiency of lifting operations. Whether you are working in construction, manufacturing, or any other industry requiring heavy lifting, understanding the key types of rigging hardware is critical to performing the job correctly. Always ensure that your rigging hardware is properly rated for the weight and type of lift required to maintain a safe working environment.

English

English Español

Español Deutsch

Deutsch 日本語

日本語