Why Galvanized Chain Shackles Are Essential in Heavy Duty Operations

Fundamental Properties of Galvanized Chain Shackles

High Strength and Durability: Typically made of high-quality alloy steel and undergoing heat treatment processes such as quenching and tempering, these shackles offer high strength and can withstand significant tensile forces. They can be used to connect high-strength chains, wire rope slings, and other applications, meeting diverse lifting requirements.

Excellent Corrosion Resistance: The galvanized surface effectively isolates air and moisture, preventing rust and corrosion. Even in harsh environments like humidity and salt spray, these shackles maintain excellent performance and extend their service life, making them suitable for marine environments and outdoor operations.

Various Specifications: Available in a variety of styles, including bow-shaped and D-shaped shackles, these shackles offer a wide range of load capacities to meet the lifting and connection needs of objects of varying weights. Each shackle is marked with a rated working load for easy selection and operation.

High Safety Factor: These shackles have a high safety factor. For example, the minimum breaking load for an S (6) grade shackle is 6 times the rated working load, and the minimum breaking load for a T (8) grade shackle is 4 times the rated working load. Furthermore, these shackles typically undergo non-destructive testing to ensure they are free of defects that could affect their strength, thus ensuring safety during use.

Easy Operation: The shackles feature a simple structural design consisting of a body and pins (or bolts). They are quick and easy to install and remove, allowing for quick connection and disconnection of the chain with other components, improving work efficiency.

Manufacturing Process and Quality Control

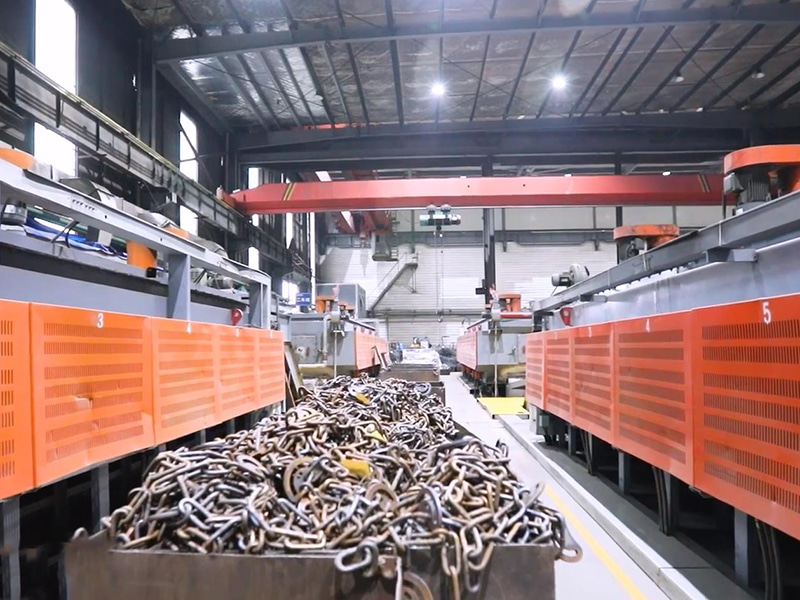

The performance of a galvanized chain shackle depends not only on the material but also on the precision of the production process. Premium carbon steel or alloy steel is selected as the raw material, which undergoes forging and heat treatment to guarantee tensile strength. Following this, hot-dip galvanizing creates a uniform coating that enhances durability and extends the service life.

Throughout this process, Shanghai TCH Metals & Machinery Co., Ltd. applies strict quality control measures to ensure that every heavy duty shackle meets international safety and reliability standards.

Applications and Advantages

The galvanized chain shackle is widely used across construction, marine transportation, cargo securing, and heavy equipment lifting. Its main advantages include:

Corrosion Resistance: The galvanized layer provides reliable protection against rust, ideal for outdoor and marine environments.

High Load Capacity: Forged structure ensures sufficient load-bearing performance, suitable for heavy machinery and cargo control.

Versatility: Compatible with rigging hardware, chains, wire ropes, and lifting accessories to meet diverse operational needs.

Along with shackles, Shanghai TCH Metals & Machinery Co., Ltd. also provides a wide range of complementary products including chains, anti-skid chains, slings, and wire ropes, delivering integrated solutions for industrial applications.

Customization and Technical Development

As industries increasingly demand precision and specialization, the galvanized chain shackle has evolved toward customized solutions. Customers can select different sizes, designs, and load ratings depending on their operational requirements.

Meeting these demands requires advanced mold development capabilities and refined equipment, combined with a focus on research and technical innovation. Leveraging these strengths, Shanghai TCH Metals & Machinery Co., Ltd. provides tailored solutions, from steel shackle designs to a variety of rigging hardware, ensuring efficient supply and consistent quality.

English

English Español

Español Deutsch

Deutsch 日本語

日本語