DIN Standard Link Chains: Compatibility with International Standards (ISO, ANSI) and Selection Guide

Understanding the differences between DIN, ISO, and ANSI chain standards is crucial for selecting the right chain. These standards vary significantly in dimensions, strength, and applications. As Shanghai TCH Metals & Machinery Co., Ltd., a leading Chinese company specializing in manufacturing and customizing DIN standard chains, we understand these compatibility issues and are dedicated to providing products that meet our clients' specific needs.

Main Differences Between DIN, ISO, and ANSI Chains

Here is a comparison of the key features of these three major chain standards.

| Feature | DIN Standard (German Institute for Standardization) | ISO Standard (International Organization for Standardization) | ANSI Standard (American National Standards Institute) |

|---|---|---|---|

| Dimensions | Uses metric units (millimeters) | Uses metric units (millimeters) | Uses imperial units (inches) |

| Design | Focuses on precision with strict tolerances and performance requirements. For example, DIN 763 long link chains and DIN 766 short link chains have specific rules for inner/outer link dimensions, wire diameter, and weld quality. | Aimed at global use, sometimes overlapping with DIN or ANSI, but may have broader tolerances. | Emphasizes interchangeability, especially in industrial power transmission chains, with strict size series like #40, #50, etc. |

| Application | Widely used in the European market for lifting, lashing, marine, and general engineering. It is very common in German-made machinery and equipment. | Globally versatile, often used for industrial power transmission and some general lifting applications. | Primarily used in the U.S. and North American markets for various transmission, conveyor, and lifting equipment. |

| Strength Grade | Has clear strength classifications like G80 and G100 for high-strength lifting. These grades are directly linked to the Working Load Limit (WLL). | Also has strength grades, but the naming convention may differ from DIN. | Strength grades are often associated with the chain number and are typically related to the breaking strength. |

How to Choose the Right Chain Standard

When selecting a chain, the most critical factors are the application environment and the equipment it will be used with.

Equipment Origin and Standards

If your equipment is from Europe (especially Germany), it is highly likely that you will need a DIN standard chain. For instance, German-made cranes or industrial hoists usually require chains that comply with the DIN standard to ensure a perfect match in dimensions and performance.

Application Requirements

- For high-strength, high-safety, and precision-critical lifting or rigging applications, the DIN standard (e.g., DIN 766) is the preferred choice.

- If the chain needs to be compatible with existing US-made equipment or transmission systems, you should choose the ANSI standard.

- For global projects or situations requiring international procurement, consider the ISO standard.

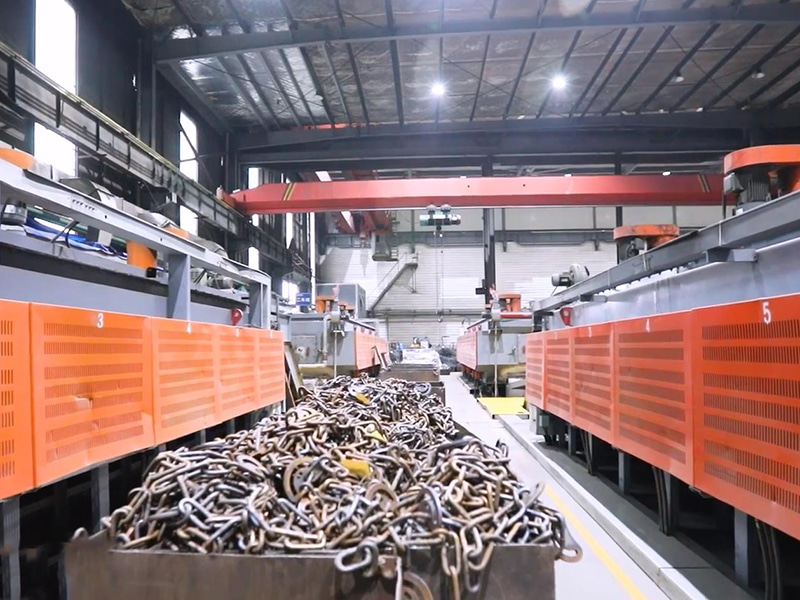

As Shanghai TCH Metals & Machinery Co., Ltd., we recognize the impact that differences in standards can have on our clients' projects. We are not only DIN Standard Link Chain Manufacturers but also a Custom DIN Standard Link Chain Factory. With our state-of-the-art manufacturing facilities and skilled craftsmanship, we can precisely control chain tolerances and performance. This ensures that every chain we produce strictly adheres to the DIN standard, guaranteeing compatibility and safety. Whether you need a standard DIN chain or have custom requirements for specific dimensions or materials, we are equipped to provide professional solutions and be your trusted partner.

English

English Español

Español Deutsch

Deutsch 日本語

日本語