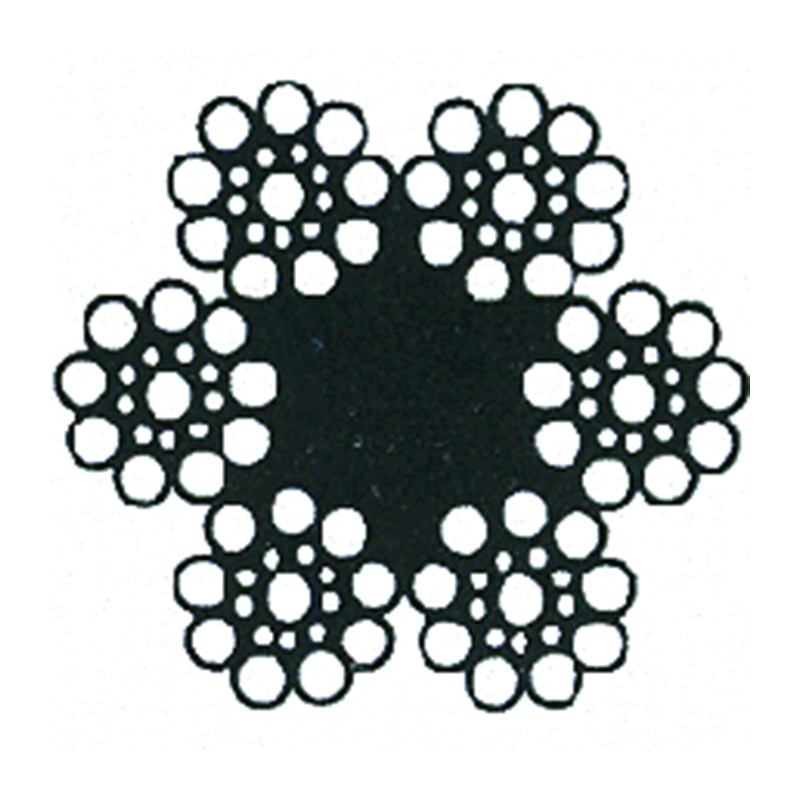

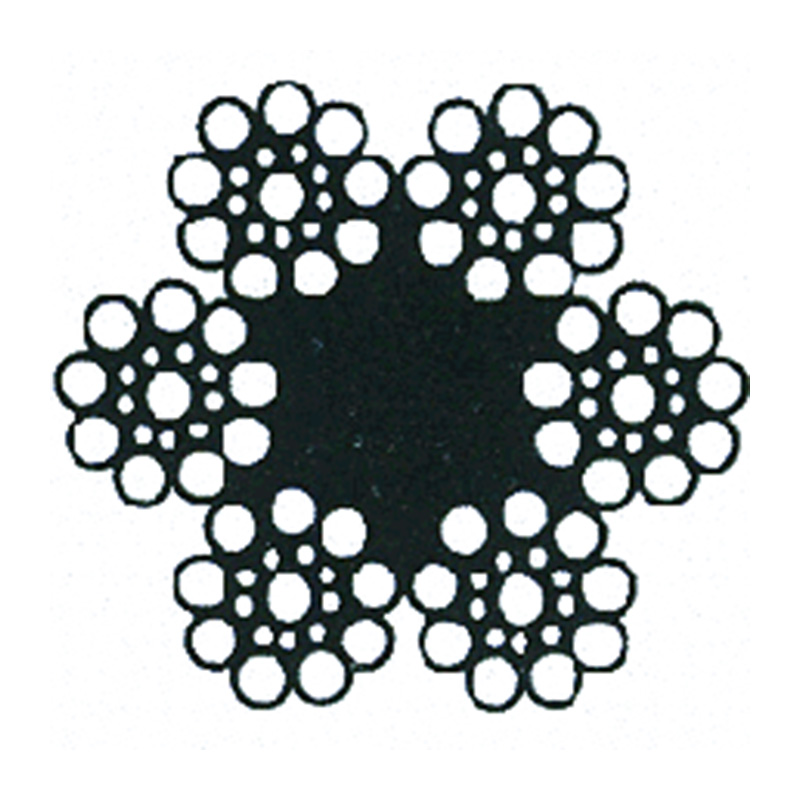

Wire Rope

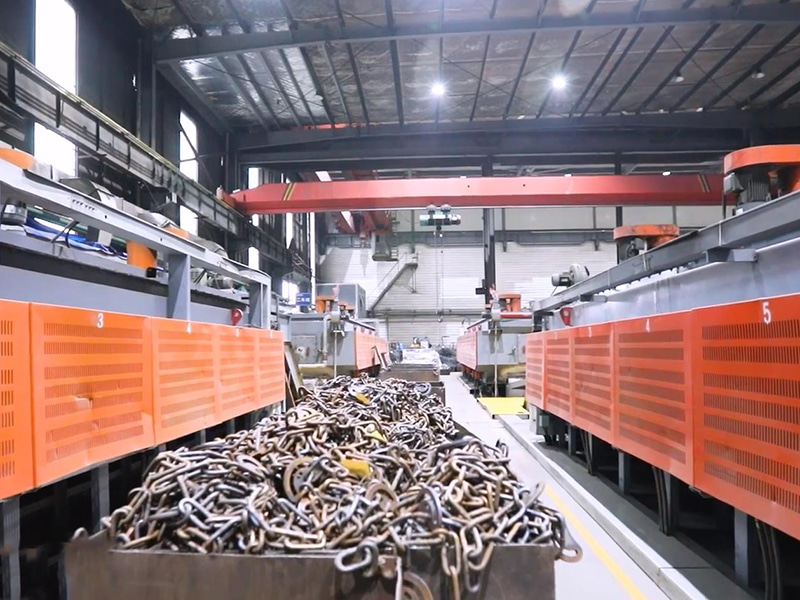

Cargo Control

Rigging Hardware

Forklift Fork

Trailer Lift Jack

Hoist

Customized Packaging Service

English

English Español

Español Deutsch

Deutsch 日本語

日本語