How to Select and Install American Standard Safety Chains

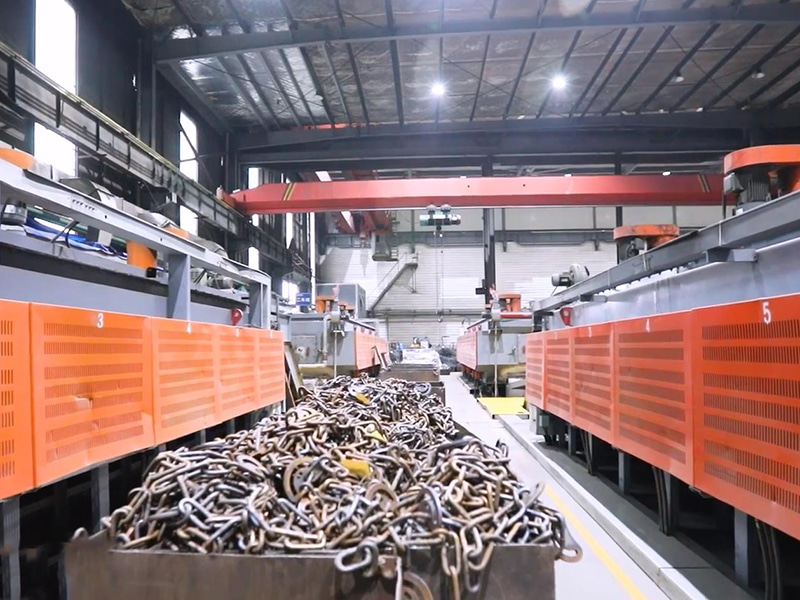

Shanghai TCH Metals & Machinery Co., Ltd. is a leading China American Standard Safety Chain Manufacturer and a Custom American Standard Safety Chain Factory. We specialize in providing high-quality metal and machinery products that meet the strictest industry standards.

Selecting ASSC-Compliant Industrial Safety Chains

Choosing the right industrial safety chain is crucial for ensuring the safety of both equipment and personnel. Here are the key factors to consider:

1. Load Capacity

The **Working Load Limit (WLL)** is a critical metric. The safety chain's rated capacity must significantly exceed the maximum expected load, typically with a safety factor of 4:1 or higher. This accounts for potential shock loads or overloads during operation.

2. Material and Finish

The operating environment dictates the required material and surface finish. For corrosive or high-temperature conditions, options like alloy steel or stainless steel with a protective finish (such as galvanization or heat treatment) are essential. Our products are designed to withstand various industrial environments, ensuring durability and reliability.

3. Chain Link Type and Size

The shape and size of the chain links must be compatible with your equipment's connection points. Ensure the links can securely attach to hooks, shackles, or other fittings without compromise. As a Custom American Standard Safety Chain Factory, we can provide tailored solutions to perfectly match your specific needs.

Installing ASSC-Compliant Industrial Safety Chains

Proper installation is just as important as proper selection. An incorrectly installed chain can fail, regardless of its quality.

1. Pre-Installation Inspection

Before installation, **always inspect the safety chain** for any signs of damage, including cracks, deformation, excessive wear, or corrosion. Never use a damaged chain.

2. Secure Connections

Ensure both ends of the chain are **securely connected** to the designated attachment points on the equipment and the load. Use compatible and properly functioning components, like shackles or specialized safety hooks, and confirm they are correctly latched or locked.

3. Eliminate Slack

Once installed, the chain should be taut with minimal slack. Excessive slack can lead to dangerous shock loading, increasing the risk of failure. While you should aim for a tight fit, allow for a small amount of play to accommodate minor movements during operation.

4. Regular Maintenance

Establish a routine inspection schedule for your safety chains. Regularly check for wear, corrosion, and damage to ensure they remain in optimal working condition. Our commitment to quality ensures that our products meet the highest standards, providing you with a reliable and safe solution for your operations.

English

English Español

Español Deutsch

Deutsch 日本語

日本語